The Natural List feature image

Industry News

The Natural Gist – What does the Dom's and Foxtrot news mean for CPG?The Natural Gist – What does the Dom's and Foxtrot news mean for CPG?

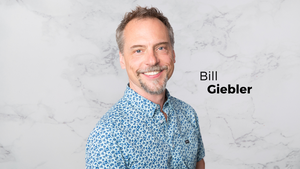

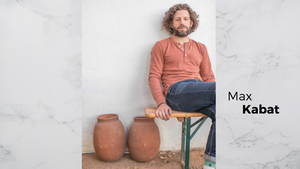

As news of the bankruptcy filing continues to spread, our industry experts talked repercussions on The Gist.

Subscribe and receive the latest updates on trends, data, events and more.

Join 57,000+ members of the natural products community.