Foundational knowledge in recycling programs and infrastructure is crucial to the pursuit of sustainable packaging.

June 8, 2020

This article was produced as a part of the Sustainable Packaging Toolkit.

When designing packaging for products, manufacturers have a plethora of variables to manage and balance. It is crucial to understand the entirety of the value chain, particularly the role of recyclers or Materials Recovery Facilities (MRFs). Ultimately, MRFs determine the true recyclability of your product and whether your packaging fulfills its intended goal.

Eco-Cycle, a mission-driven, nonprofit recycler based in Boulder, Colorado, is a leader in resource conservation. In this interview Kate Bailey, policy and research director at Eco-Cycle, provides crucial context for our recycling systems, explains how to design packaging for recycling and outlines key issues with plastics in our recycling system.

Eco-Cycle, a mission-driven, nonprofit recycler based in Boulder, Colorado, is a leader in resource conservation. In this interview Kate Bailey, policy and research director at Eco-Cycle, provides crucial context for our recycling systems, explains how to design packaging for recycling and outlines key issues with plastics in our recycling system.

How does our recycling system work?

Why is it important to recycle?

Kate Bailey: Recycling has been called the No. 1 thing we can do for the environment by the U.S. Environmental Protection Agency. Recycling is a critical component of a sustainable, circular economy and is crucial to maximizing natural resources, saving water, energy and creating more resilient communities. Recycling is also one of the fastest, easiest and most cost-effective ways to reduce our climate impact—recycling 1 ton of materials saves 3 tons of carbon emissions. Here are the top five reasons why we recycle.

What happens to recyclables once they are picked up?

KB: In a single-stream recycling program, all recyclables—paper, plastic, glass, steel, cartons and aluminum—are collected in the same cart and sent to a Materials Recovery Facility (MRF). Most MRFs use a combination of people and automated equipment to sort the materials back into their respective material types. The materials are then compressed to make bales and sold to manufacturers around the country, and sometimes the world, to be used to make new products. Check out this video on how a MRF works and then use this map to find a MRF near you. (Insider tip: MRF tours are a great way to engage employees on how and why to recycle.)

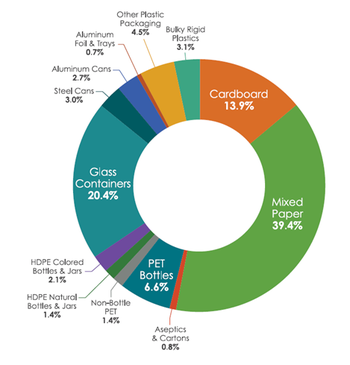

What do we currently recycle?

KB: Chart courtesy of The Recycling Partnership, State of Curbside Recycling 2020.

Paper: More than half of what we recycle is paper, including cardboard boxes, cereal boxes, newspaper, etc. Paper can be recycled into new products as many as seven times. Paper that comes into contact with food, such as paper towels or tissues, is not recyclable.

Metals: Metal is infinitely recyclable. Aluminum cans and steel/tin cans are accepted in nearly every recycling program. Unfortunately, the U.S. still only recycles just over half of our aluminum cans.

Glass: Glass bottles and jars are infinitely recyclable, but glass is heavy which makes it expensive to ship it over long distances. More than any other recyclable material, glass recycling really depends on having a local user of the glass, preferably a bottling company.

Plastic: Plastic bottles, jars and jugs are widely recycled throughout the U.S. and you can have confidence that these materials continue to be recycled. Other plastics are extremely challenging to recycle because there are no buyers for these materials, and they are expensive to collect and sort for a low volume of material. See more on which plastics can be recycled below.

Designing your product for recyclability

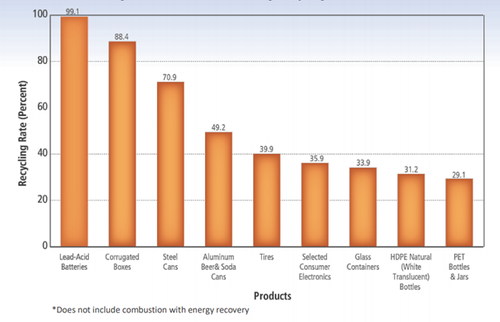

How well do we recycle packaging?

KB: Recycling rates vary widely by the type of product or packaging. Here in the U.S., we recycle more than 88% of cardboard boxes but only 30% of plastic bottles. In general, we are much worse at recycling plastics than other materials.

Who can I ask to find out if my product/packaging is recyclable or if it will be recyclable in the future?

KB: There is no definitive source that can say if a package is universally recyclable, but there are some really good places that can help get you started. These include:

Talking to your local recycling company about the recyclability of your packaging and any challenges you might have in terms of recycling the product. Recyclers like Eco-Cycle are happy to discuss when a package can be recycled before you pursue the label.

Checking out the How2Recycle label, a national initiative with the aim of effectively communicating how to recycle or compost any product. Your package will be assessed on its recyclability across the U.S. and then assigned the appropriate label.

Using these worksheets from the Sustainable Packaging Coalition to dive deeper into how your packaging design affects the collecting, sorting and recycling of your product.

How can I design my product/packaging to be more recyclable?

KB: Many industry associations have recycling design guidelines that you can follow. For example, the Association for Plastics Recyclers offers design guidelines around labels, closures, colors and other attributes to make your plastic packaging more recyclable. However, for packaging types like pouches that are currently unrecyclable, there is a lot of work that needs to be done to change the recycling system. The best advice is to get involved with a cross-industry collaboration initiative to work with packaging designers, brands, recyclers and others to co-create new solutions, such as RCD Packaging, OSC2’s Packaging Collaborative or the Climate Collaborative.

What are some common mistakes to avoid in designing packaging to be more recyclable?

KB: To avoid making mistakes in terms of design packaging, you can:

Ask for clarification on how it can be recycled. Some materials like plastic bags can be recycled but only through mail-back or in-store take-back programs. That’s not the same as curbside recycling and has a lower collection rate.

Changing the design can make it non-recyclable. Shrink wrap labels on aluminum cans or plastic bottles make it very hard to sort and recycle these products. Color also matters: Black plastics are more challenging to recycle.

Designing for recycling doesn’t mean it will get recycled. Many products can be designed to be recyclable but that doesn’t mean that they are accepted in recycling programs. Talk to recyclers about what is accepted.

Don’t leave the consumer guessing. Consumers first look at a product's label to see whether it can be recycled or composted. Give them adequate instructions on what to do, as is illustrated by the How2Recycle label.

Obstacles when recycling plastics

Which plastics are recyclable?

KB: You’ll find the recycling symbol on almost all plastics, but in reality most plastics AREN’T recyclable. The chasing arrows symbol does not indicate whether a plastic material can be recycled. In general the shape of the plastic is a better way to know if it’s likely recyclable. Eco-Cycle’s guidelines emphasize the shape of the plastics. Most communities accept plastic bottles, jugs and jars for recycling. Beyond that, nearly all other plastics are not recyclable, which is why there is a lot of emphasis on finding ways to reduce, reuse and redesign plastics.

We recommend choosing #1 PET, #2 HDPE and #5 PP as they are the most recyclable, least toxic plastics to use in making your products and packaging. We recommend avoiding #3 PVC, #6 PS/EPS and #7 plastics because they are more toxic and less recyclable. Check out this chart for a quick run-down of the plastic codes.

Why is it so challenging to recycle pouches and other flexible film recycling?

KB: Pouches and other flexible plastic packaging are very hard to recycle for three main reasons:

Buyers for flexible plastic are very limited: Recycling facilities depend on being able to sell their sorted materials and subsequently have them made into new products. There are very few buyers for flexible packaging because this packaging includes many different types of plastic layers, adhesives, closures, metalized layers, etc. These layers are nearly impossible to separate and limit how the packaging can be recycled into a new product.

They're hard to sort: Thin film and flexible packaging is one of the most problematic materials at recycling facilities because it gets tangled up in the gears of the sorting equipment. It is also very challenging to separate these thin plastics from paper materials at the MRF, which makes it harder to sell the paper for recycling.

High costs for collecting and sorting: The costs to collect and sort flexible packaging are much higher than the price paid for the materials by the end market, so a recycling facility would lose money by collecting these materials.

What about store take-back programs for film plastics?

KB: Many retail stores and community drop-off centers offer recycling programs for film plastics such as plastic bags, bread bags and the wrap around your toilet paper (see a complete list here). Some of these programs are expanding to accept some types of flexible film pouches that have been specifically designed to be compatible with these programs. These film plastics are commonly recycled into composite lumber used for making decks, benches and playground sets. While these programs are a good start to expanding recycling programs, they have limited effectiveness: Only about 4% of residents participate in store take-back programs.

What the best thing brands can do right now to support more recycling?

KB: Using recycled materials in your products and packaging is the most important step you can take right now to help improve recycling. Start today by asking how much recycled content is in all your packaging and labels, and then commit to increasing your use of PCR content and challenge your competitors to do the same.

Ask for the highest amount of post-consumer recycled (PCR) content in all your products and packaging, because purchasing PCR content ensures that there is a strong demand for recycled materials and gives recyclers a place to sell what is collected. Get inspired by the Recycling Demand Champions program.

About the Author(s)

You May Also Like