How this upcycled brand built a 'farm-to-shelf' supply chain

Barnana incentivizes South American farmers to incorporate regenerative practices, and its farmer network is rapidly expanding.

November 9, 2021

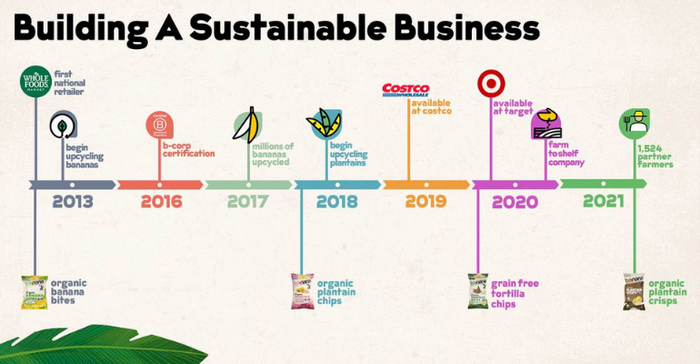

When Cauê Suplicy founded Barnana, a Certified B Corporation, he wanted to reduce food waste and get healthier banana- and plantain-based snacks to the United States.

Three years ago, Barnana was working with 200 farmers. It now works with more than 1,500 farmers, mostly in the Amazon region of Ecuador, and hopes to double that number in the next five years while expanding into other countries, Suplicy said. The goal: help farmers transition their land by using regenerative practices and create a better supply chain by purchasing their fruit before it becomes certified organic.

“We approach indigenous farmers that have been growing bananas in a conventional way and help them become certified organic,” Suplicy said. “It's very easy for companies to tell farmers ‘You should start growing organic and once you become certified, we'll buy from you.’ But that is a very long and complex process, especially if you are in the middle of the Amazon.”

To help with the transition, Barnana commits to buying from farmers once they start using organic practices, even though they’re not certified. It’s why Barnana recently added grain-free, non-GMO plantain tortilla chips to its line-up that is otherwise organic, Suplicy said.

“It’s important for more companies to help farmers transition to organic,” Suplicy said. “And to give them an outlet to sell their products.”

Barnana, which is headquartered in California, upcycles bananas and plantains that are considered too big and long, too small and curved or too ripe to be transported, and turns them into dehydrated banana bites, plantain chips and crisps, among other natural food products.

“Fruit is extremely difficult to control, especially when trying to get the right shape and size, or the timing right for ripening,” said Suplicy, who is from Brazil and is a founding member of the Upcycled Food Association. “Bananas can go from very green to very ripe in five days. We get bananas that don't qualify to be sold as fresh.”

Barnana has upcycled more than 50 million bananas and plantains since 2013—including 3.2 million bananas and 8.6 million plantains last year, according to a company spokesperson.

In September, Barnana acquired its Latin American supply and manufacturing partner, Agroapoyo in Quito, Ecuador, to create a “farm-to-shelf” supply chain.

That�’s helped Barnana solve some of the “transportation and ingredient issues that are plaguing many of us,” Suplicy said.

Below, read more about Barnana’s push to increase regenerative farming and upcycle organic bananas and plantains.

Why did you start working with organic farmers in the Amazon?

Cauê Suplicy: When I started this company, all I wanted to do was bring healthier products to the United States. I didn’t know that I was going to work with farmers in the Amazon. I just had a vision. I was raised eating dehydrated fruits like candy and wanted to sell it.

I never thought it was possible to work with small farmers like we do now in the Amazon.

How did you eventually connect with local farmers?

CS: Originally, we had this idea that for a company to be successful and to be able to scale you had to work with factory farmers where you have big machines.

That is just not the case. It does take more work to do what we do, but it pays off because you’re impacting so many more people. Once you are at an organic farm, you see the difference. It is just night and day. You're protecting the environment. You're protecting people's lives. You feel a lot better going to work every day.

What suggestions do you have for other business owners who are trying to make food systems more efficient, equitable and sustainable?

CS: When I was in the early stages of launching this company, I met Ryan Black [CEO and co-founder of Sambazon]. I was having a hard time finding organic growers. It felt too difficult, too expensive. He told me to stick with it, that once I got it going, it would be worth it and pay off. Now I understand. It’s totally worth it.

How did you get into upcycling?

CS: I was visiting an organic farm and saw bananas being washed and packed. I noticed there was a percentage of bananas that weren’t being boxed and just thrown to the side. The pile kept growing and growing. I didn’t understand why they weren’t being packed. To my untrained eye, they were exactly the same.

What makes bananas (and plantains) good for shipping as fresh fruit?

CS: Bananas need to be extremely green when they are exported. They are put into cold containers to stay green until they get to the country that’s buying them. Then they are put into ripening rooms. If a banana is green with a little yellow halo, the ripening process has already started and you can’t stop it. So many of them don’t make the cut to be exported.

Why are so many bananas just tossed to the side? It boggles my mind with so many food shortages.

CS: It’s a faulty supply chain. It starts with our love of bananas, which are the No. 1 food item in grocery stores. In the United States, with over 300 million people, we eat a lot of bananas. You can find them everywhere, Starbucks, Costco, grocery stores and even gas stations. The production to feed this country is ginormous.

So what happens during the supply chain?

CS: In order to transport the bananas safely, they need to box them. Only certain shapes and sizes of bananas fit into a box to get it the right weight and get it secure for shipping. It's almost like you are playing a Tetris game with bananas.

If the banana doesn't fit that mold, it cannot be exported, if it is very large and straight, or small and has a big curvature, it doesn't fit that mold. Or, if it’s starting to ripen.

Why is it difficult to sell fresh fruit that can’t be shipped?

CS: Brazil, where I’m from originally, is one of the largest producers of bananas. Most of the bananas that can’t be shipped have places to be sold locally because the country is large with over 200 million people.

In small countries, such as Ecuador, Costa Rica and Columbia, that have a very large production of bananas, there’s not many places for them to locally sell bananas that can’t be shipped when they are producing for a massive market like the U.S.

About the Author(s)

You May Also Like